Introduction of fly ash silo

Fly ash is a useful material in a lot of areas, it is one of the product after the burning of coal, composed by exiguous particles that are driven out of a boiler with the flue gases. In chemical and physical, there are many forms of fly ash, the typical type of fly ash contains much silicon dioxide and calcium oxide, which make it frictional and abrasive. Usually, the size distribution of fly ash with most less than 100microns. It is a kind of material that hard to handle because of it’s characteristic of fine particle size, frictional nature and high temperature. Nowadays, fly ash is captured by electrostatic precipitators or other particle filtration equipment generally before the flue gas reaches the chimneys. With the coal ash that removed from the bottom of the boiler together called fly ash.

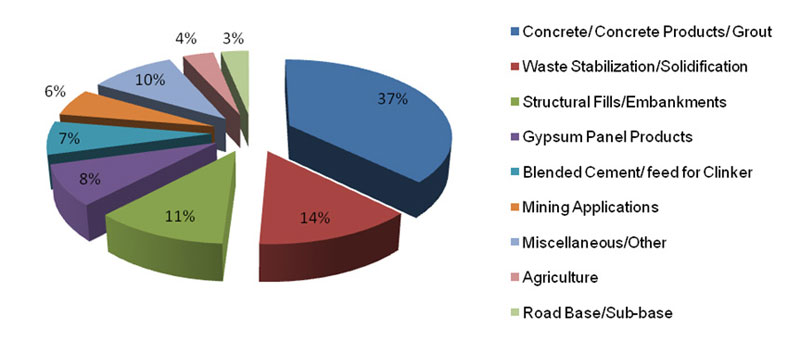

Fly ash is wildly used in many areas, here are some examples, fly ash is a necessary building material that we can usually seen in cement production, embankment and other road construction. Anyway, fly ash is a useful material in different industries. Since the fly ash applies in so many areas, there is also a potential risk behind the using of fly ash, environmental pollution and ground water contamination. It is necessary to store the fly ash well.

Advantages of Fly ash silo

- Advanced technology. Flyer fly ash silo adopts the most advanced silo building technology form a Germany engineer. The double-seam technology makes the silo seals extremely well and stable.

- High quality material. Flyer has a long term cooperation with Han-Steel. Han-Steel was one of the steel supplier of the manufacture of the 2008 Olympic stadium, Bird Nest.

- Stable performance. Flyer fly ash silo is designed to meet the customer’s requirements, the structure is stable and the maintenance of the silo is easy and simple.

- Low cost. Flyer steel ash silo is simple in structure and it is easy to construct. The construction period is short and need less workers than other silo. The silo can serve at least 35 years.

First of all, in the construction site of fly ash silo, you should set up temporary warning signs to warn that no irrelevant person should ever enter the construction site.

Seal the pipe where fly ash comes into the silo, and tie the wire up, set warning signs.

When there's no fly ash in the silo, the downstream equipment such as the bottom of the base should be put into the maintenance position.

Library lighting lamps should be placed into the fly ash silo from the hole in the middle of the top, the cleaning staff should not be exposed to lighting tools and lines.

In the fly ash silo cleaning process, the number of people outside the silo should be twice the number of people in it. And professional staff should be sent to monitor outside the fly ash silo.

After the safety of base stacking and the ladder’s stability have been confirmed, you can enter the silo.

To enter the fly ash silo, the construction workers should wear labor protective equipment first, including anti-dust masks, goggles, safety shoes, and safety helmets.

When entering the fly ash silo, the workers have to fasten two safety ropes, one fixed in the library outside the dust collection device support, the other fixed on the ladder.

When the cleaning starts, the feed rate of the mill should be based on the flow; if the flow is too small, put ash in the upper part of the rotor balance pipe, and put down the fly ash mixed with the mixed material to do the mixture.

The iron bars and compressed air are used to poke the fly ash to the bottom of the pool, and then blow out the compressed air at the top of the silo; after the compressed air is blown out, the long stick is used to stick the fly ash, and last, use shovel and pick to put it into the silo. Please notice: people should beware of the falling material and keep distance from them at the beginning.

If you need high-altitude operation in the fly ash warehouse, you should strictly abide by the relevant provisions of high-altitude operations.

It is prohibited to use explosives to clean up the fly ash silo.

When the process of coal ash silo cleaning is finished after the completion of a thorough clean-up, the cleaning work can be over.